Ultrasonic Cleaning Equipment – Options for a Variety of Needs

September 23, 2017 by tina

Ultrasonic cleaning equipment has emerged to be an efficient and environmentally sound solution for challenging parts cleaning applications.

Solvent degreasing with Sodium Hydroxide is widely used as an efficient solution for parts washing. More environmentally-friendly water-based substitutes such as aqueous degreasers, citrus degreasers, and petroleum based chemistries have been introduced, however they can be less effective and may not perform adequately in some applications. Ultrasonic energy provides a mechanical energy boost when used with these solutions to assure the necessary levels of cleanliness. Ultrasonic cleaning equipment is now used extensively in critical cleaning applications to both speed up and enhance the cleaning effect of alternative chemistries.

Ultrasonic cleaning equipment is available in a wide range of configurations to suit a variety of application needs. Options include individual ultrasonic tanks, multi-tank ultrasonic cleaning systems, as well as single piece flow-through ultrasonic conveyor systems. Leading developers of ultrasonic parts cleaning equipment offer pre-engineered platforms in a variety of tank sizes and configurations to accommodate a customized approach to meeting the most widely needed customer specifications.

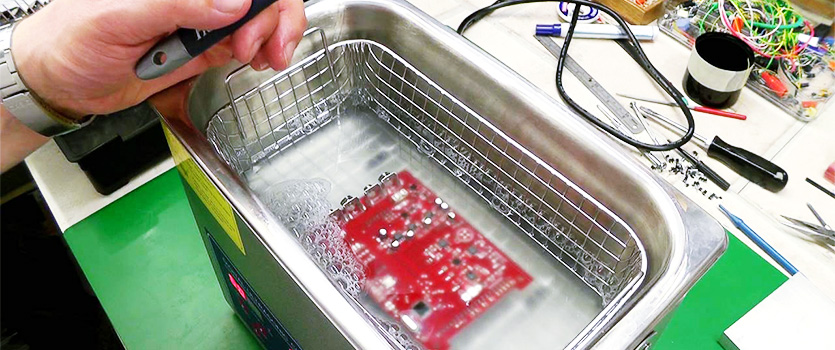

Another option for ultrasonic parts cleaning is benchtop ultrasonic cleaning tanks. These systems offer a cost efficient way to add the power of ultrasonic cleaning to any parts washing process. Portable and self-contained, benchtop ultrasonic cleaning tanks are equipped with electric heat and operate from readily available electrical supplies. They are offered in a variety of standard sizes and can be engineered for custom applications.

Some ultrasonic cleaning technologies are available in component form. This gives manufacturers the option to retrofit existing equipment. OEM fabricators may also incorporate these components into new machine designs. Immersible transducers or transducer plates are made in standard configurations or engineered to size for incorporation into tanks. These components can be either bolted or welded into place. Transducer elements can also be added directly to custom fabricated tanks.